1923 Dennis Trailer Pump

![]()

This is a 1923 Dennis trailer pump on solid tyred disk wheels. It is fitted with the Dennis No.2 pump which was only in the second year of use with Dennis. The engine rather than being a White and Poppe unit is a four cylinder Dorman. Rated power output is 20HP. Unfortunately the pump has been partially disassembled for and some parts are missing. The sump has not been in place for many years which has resulted in the crankshaft being rusted into position. The tappet pushers are also siezed solid.

The pump was delivered new to Woburn Abbey, however during the 1960's it was returned to the Dennis factory at Woodbridge Hill, Guildford, where it is pictured above. The pump remained there until the factory was demolished. Finally in 2008 with the current owner, serious restoration has now begun. The previous page (CLICK HERE) showed the manufacture of a new water pump for the engine, this page shows the manufacture of other components and the freeing of the engine from the grip of rust and corrosion.

Fortunately Frank Cerruti a Dennis collector in Queensland spotted this early Tamini pump mounted on the front of a Bean. This pump is identical to the fire fighting water pump mounted on the Woburn unit. From this photograph it has been possible to re-make all the missing pump components.

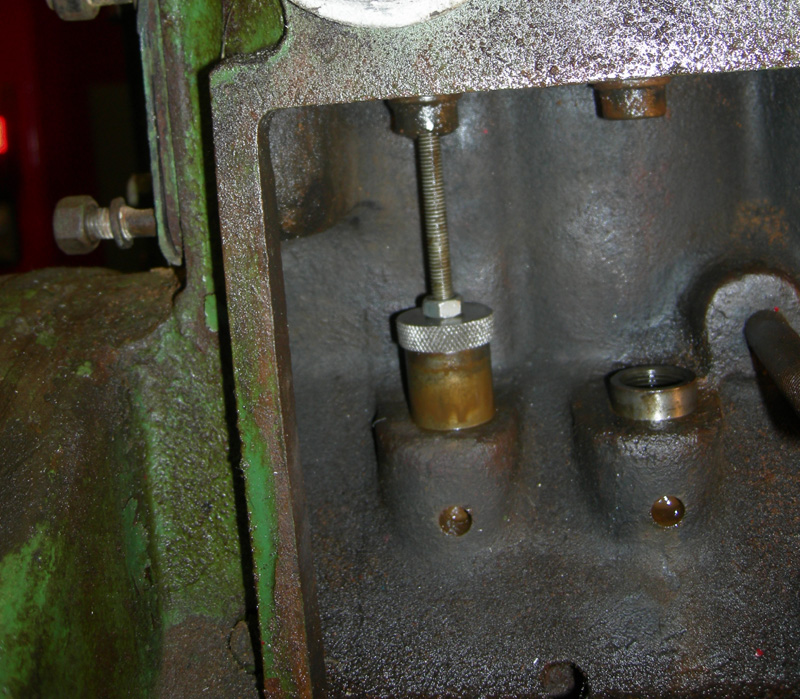

The engine which is fitted to this pump was manufactured by Dorman. It is a sidevalve unit where the cam shaft operates directly on cam-followers/pushrods which act directly on the end of the valve stems. On the end of each pushrod is a tappet adjuster. Through standing for many years without the protection of the tappet covers the pushrods were totally siezed into the engine block. The valves were removed by unscrewing the valve caps to gain access to the tappets which were then also removed. A simple extractor was then made to pull the pushrod upwards. Once some movement of the pushrods was achieved it was possible to free the units completely with patience and penetrating oil.

Three of the four pistons freed off quite easily, but number 2 piston was firmly stuck. At some time number two cylinder had been filled with water for a considerable time. The solution was to fill the cylinder with WD40 and then cap the cylinder with a temporary aluminium plate so that the cylinder could be pressurised at 150psi. After standing for two weeks at this pressure the WD40 started to weep past the piston skirt and then it was only a quick tap with the mallet away from being free.

A new header tank has also had to be made. This has been produced from 2mm steel sheet. A top and bottom 'U' shape section are overlapped and then soldered and riveted as the original constructional technique.

To neatly overlap the sides the lower half needs to be 'joggled'. This is a folded recess to accept the metal from the upper half of the 'U' section. This is achieved by repeatedly passing the metal through a set of rolls fitted with two rollers of the correct 'joggle' profile. This is a technique that has been used for as long sheet metal has been worked. My joggler must be as old as the trailer pump itself.

For the next stage of the restoration CLICK HERE

![]()